Power reliability starts with smart prep and code-aware choices. When faults appear, response time matters, but so does method. We map hazards and protections before turning a single screw. That approach helps in emergencies and in routine upgrades, and it’s crucial when you call an Emergency Electrician for urgent faults. You’ll see how we use protective steps and how we coordinate shop access, materials, and schedules. Fast work is good, but safer work is better. In this guide, we outline simple checklists that avoid rework, from parts selection to testing. You’ll also get short scenarios that explain why a methodical process beats guesswork every time. Pick a path that matches your risk tolerance, and keep your system steady.

Scoping the job and safeguarding early with clear steps

Start by listing what fails and what must stay live. For time-sensitive calls, review access points urgent power fault repair with any limits on shutdowns before we mobilize. Map devices, breaker sizes, and any AFCI needs, then confirm labels match reality. A rushed start invites mistakes. We prefer a two-pass check. That routine spots overheating lugs before you escalate to bigger work. In a small cafe, for example, we log refrigeration circuits and plan testing after closing to avoid spoilage.

Define go/no-go gates for scope creep, like if insulation tests fail on a feeder. Build a job card that names the panels, rooms, and runs to touch, along with expected sign-offs. This keeps the team aligned. Coordinate with neighbors or tenants for access windows and elevator bookings. Simple alignment saves hours later. If a landlord needs proof, offer a short plan with target risks and mitigations.

Selecting parts, ratings, and compliant materials that last

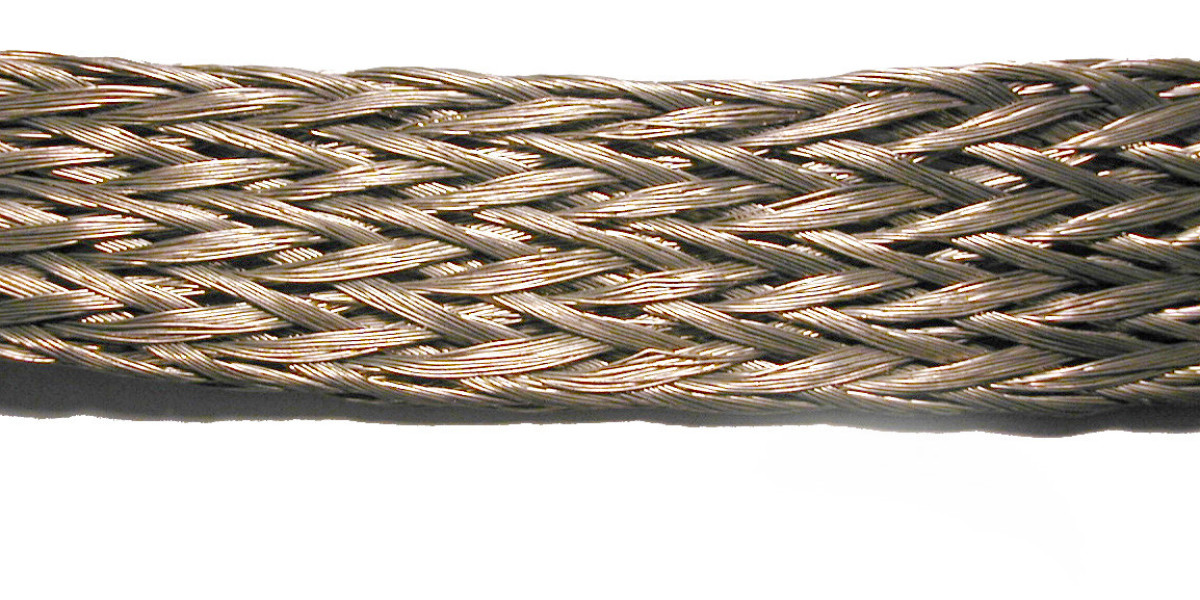

Choose components that match ambient heat rather than just the cheapest box. For critical circuits, compare temperature ratings smart home installation and verify torque specs published by the manufacturer. Dissimilar metals need anti-oxidant and correct pressure. Pick breakers with verified interruption capacity for the service rating. Protection only works when upstream devices are matched. We often stock UL-listed lugs to avoid delays.

Cables, boxes, and fittings must suit the moisture and vibration. Kitchens benefit from gasketed covers. For retrofits, check conductor fill before adding another circuit in a jammed raceway. Tight spaces raise heat. When homeowners ask about options, we explain how Electrical Services combine correct ratings with long warranties, so the whole system ages better.

Coordinating workflow, timing, and steady communication windows

Reverse-plan the schedule from go-live so inspections land on weekday mornings that suit the authority. Confirm staging areas for tools certified electrician in London and decide when to shut down nonessential circuits. We keep one person on client updates, because silence causes stress. For a salon, we might shift heavy testing to Monday, then wire on Tuesday afternoon when foot traffic dips. That kind of shuffle avoids cancellations.

Sequence tasks to minimize live exposure. Cover floors, post notices, and test alarms. One change at a time beats chaos. Use Electrician Services to bundle site prep, install, and cleanup into a single visit where possible. Fewer handoffs reduce error, and the service window stays predictable even if a detector fails and needs swap-out.

Verifying quality, managing hazards, and documenting test results

Adopt a test-first mindset with calibrated meters and a repeatable checklist. Start with voltage checks at the main, then insulation resistance www.electricianslondon247.co.uk on suspect runs before energizing. We prefer to catch faults cold. Include torque checks with a known wrench and record the values. Good records win inspections, especially in light commercial settings.

Walk the job slowly with covers off, confirm labeling, and photograph any junctions of interest. Test GFCI and AFCI operations with the right simulators and note results in the report. If anything drifts, we pause and fix. In a duplex remodel, we phased testing by floor to keep one kitchen live. For urgent calls, an on-call emergency electrician follows the same checks, just faster and in tighter windows.

Balancing cost, trade-offs, and lifecycle value choices

Budget choices should weigh energy use against replacement cycles and access limits. When comparing fixtures, include maintenance reach domestic and commercial electricians and lamp life, not only sticker price. Lower price today may mean frequent trips. We show a one-year and five-year projection, so owners see real totals. That view calms decision fatigue and help avoid corner-cutting.

Pick upgrades that cut hot spots and extend intervals between visits. A better breaker and clean terminations pay back. For a small office, we swapped buzzing ballasts and added surge protection to protect PCs. Outages fell to near zero. If a future expansion is likely, choose panels with spare capacity so you won’t redo upstream work later. Right-sizing reduces rework across the building’s life.

Aligning with clients, trades, and smooth approvals across the board

Good coordination starts with simple language and a shared timeline. We set expectations about noise, dust, and power windows Electricians London 247 services so people can plan their day. Respect for routines keeps trust high. In a daycare, that might mean testing after pickup and cleaning before the morning rush. Details make the difference when operating around children or seniors.

Sync with HVAC and carpentry when walls open, so everyone finishes once. No one likes rework, and tight calendars need clean handoffs. Share panel schedules, label conventions, and photos so the next tech can follow the story. Future techs will thank you. For after-hours faults, we keep a quick-start plan on file, making handovers painless if new staff is on-site.

In short, start with careful scope, choose durable materials, and schedule around real-world constraints. Verify work with disciplined tests, and look beyond sticker price to total value. Use clear coordination so tenants, staff, and vendors move smoothly through each phase. With that approach, urgent calls stay calm, routine jobs finish cleanly, and systems stay safe for years.